The PoroTwin project

A digital twin with real-time integration of reservoir flow, simulation and control with experimental operational parameters

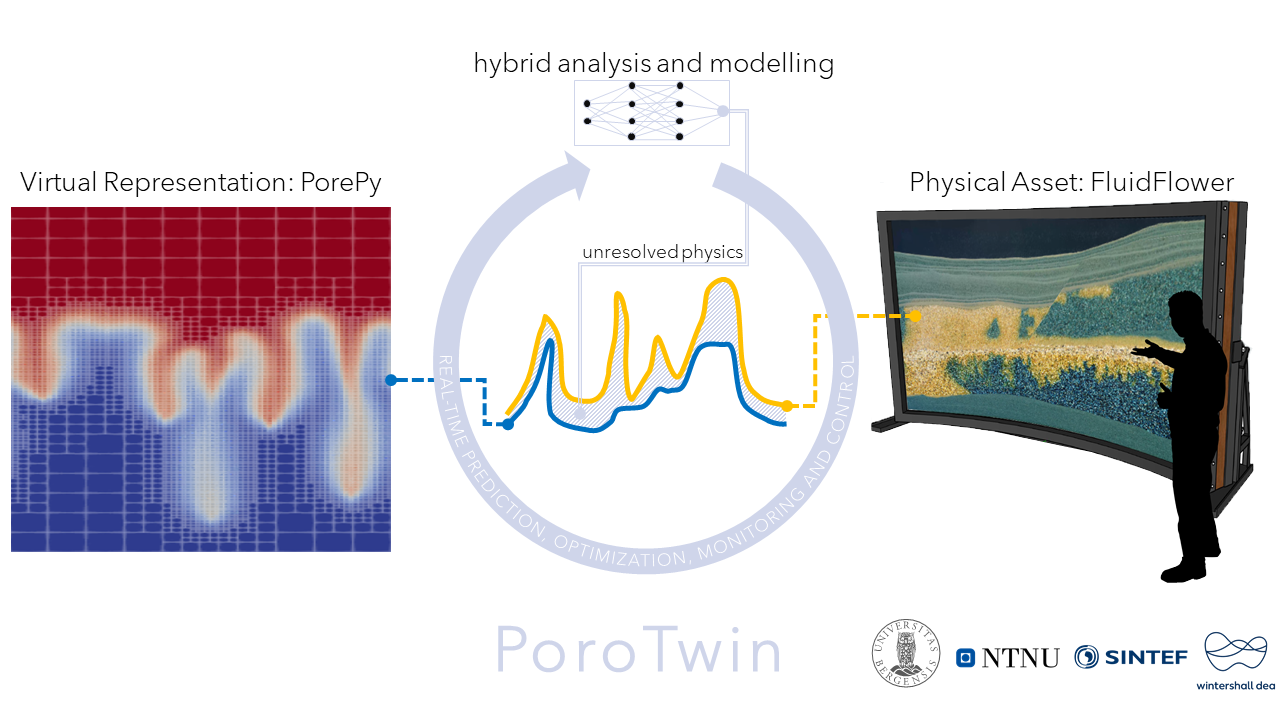

Digital twin can be defined as a virtual representation of a physical asset enabled through data and simulators for real-time prediction, optimization, monitoring, controlling, and improved decision making. – Rasheed et al. 2020

Vision of the PoroTwin project

The FluidFlower rig provides a unique possibility for designing, calibrating and validating a digital twin. The reservoir properties and geometry are easily obtained, and high-resolution facies maps and petrophysical properties are therefore available for reservoir simulation.

The traditional industrial workflow use the reservoir simulator as a planning and decision-making tool, wherein data are integrated via history matching to improve simulator parameterization.

The PoroTwin project enables us to go beyond standard workflows to explore the potential of the reservoir simulator using a true digital twin.

Description of the PoroTwin project

To achieve the vision outlined above, the following key technical steps must be implemented:

1. Achieve fully automated monitoring and transmission of experimental data to the PorePy simulator.

2. Integration of the PorePy simulator into the Hybrid Analysis and Modeling (HAM) framework.

3. Implementation of a flexible real-time automatic control environment.

4. A software bridge to allow for real-time control of FluidFlower operating conditions (injection rate and wellhead pressure).

With the technical steps listed above in place, we can fully integrate the experimental FluidFlower with the state-of the art PorePy simulator.

Hence, the PoroTwin project creates the potential for using flexible data assimilation and automatic control environments to unlock the capabilities of digital twin technology for multiphase flow in porous media.

Participating academic institutions

The PoroTwin development is funded by Wintershall DEA.